How an Aluminum Foundry ensures accuracy through advanced technology

Finest Practices for Upkeep and Applications in the Light Weight Aluminum Foundry Field: A Detailed Summary

Preserving devices in the light weight aluminum factory field is essential for operational success. Routine inspections and predictive maintenance can significantly decrease downtime and improve security. Advanced technologies, such as IoT and data analytics, play a critical role in this process. Understanding the full range of best practices requires a closer assessment of details approaches and their influences on efficiency. What are the crucial components that contribute to a trustworthy upkeep framework?

Relevance of Regular Maintenance in Aluminum Foundries

Regular maintenance plays a vital role in the reliable procedure of aluminum foundries. By methodically inspecting and servicing tools, factories guarantee peak efficiency and durability of machinery. Normal upkeep activities, such as cleansing, lubrication, and element replacement, aid stop unexpected breakdowns that can bring about expensive downtime.

Moreover, routine checks enhance work environment safety by determining potential dangers prior to they escalate into severe concerns. Devices that is well-maintained operates better, causing improved product high quality and lowered waste. Additionally, adherence to an organized upkeep schedule can support compliance with sector regulations, thus promoting a credibility for dependability and top quality within the market.

Executing Anticipating Upkeep Strategies

Predictive upkeep strategies take the principles of routine upkeep an action further by leveraging data analytics and advanced tracking innovations. In light weight aluminum shops, these approaches make it possible for drivers to anticipate equipment failures before they occur, thus minimizing unexpected downtimes and enhancing functional performance. By making use of sensing units and IoT tools, real-time information can be accumulated on equipment efficiency, enabling the recognition of prospective problems with predictive analytics.

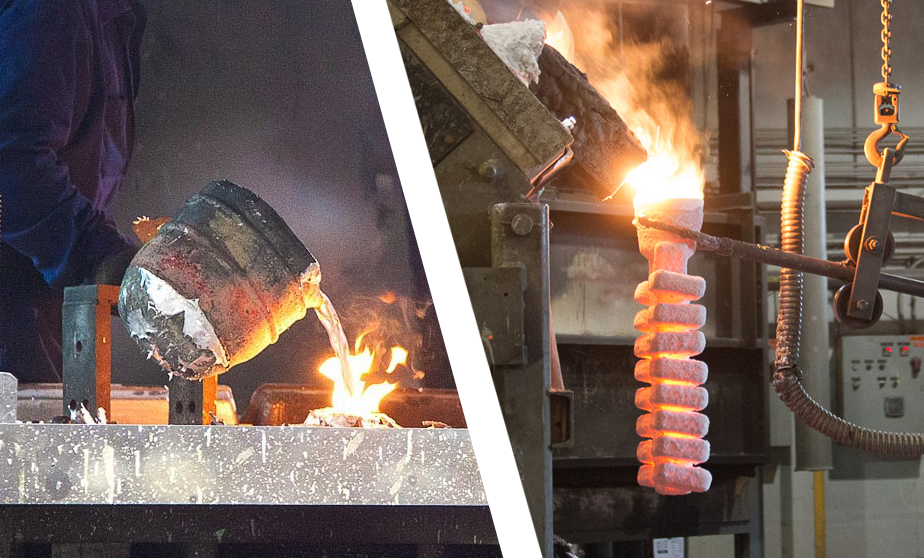

Enhancing Melting and Pouring Processes

Efficient melting and pouring processes are vital for making the most of efficiency and guaranteeing the high quality of aluminum castings. To enhance these processes, foundries should concentrate on accurate temperature level control during melting, as this straight influences the metallurgical homes of the alloy. Using sophisticated melting innovations, such as induction and resistance melting, can boost energy efficiency and reduce cycle times.

Implementing automated putting systems reduces human mistake and preserves consistency in the putting process. Correct mold preparation, consisting of adequate preheating, is important to protect against thermal shock and enhance mold and mildew durability.

Enhancing Security Methods in Foundry Workflow

Focusing on safety in aluminum factory procedures is vital for safeguarding employees and assuring a productive atmosphere. Efficient safety and security methods include regular training sessions that highlight the value of individual safety equipment (PPE), such as goggles, gloves, and helmets. Furthermore, the establishment of clear emergency procedures is vital in handling prospective mishaps.

Routine evaluations of devices and machinery help identify hazards before they rise right into significant concerns. Carrying out a durable reporting system encourages workers to communicate safety and security concerns without anxiety of effect. Cultivating a society of security assurances that every employee recognizes their function in maintaining a safe and secure office.

Furthermore, guaranteeing correct air flow and monitoring air top quality can alleviate exposure to harmful fumes and dirt. By strengthening these techniques, light weight aluminum foundries can substantially minimize the risk of crashes and produce an environment where staff members feel valued and secure, inevitably improving total operational efficiency.

Leveraging Innovation for Improved Efficiency

Making use of sophisticated innovation has actually become progressively important for light weight aluminum shops aiming to improve functional performance. Automation and robotics play an important function in simplifying production processes, minimizing labor prices, and reducing human error. Carrying out real-time tracking systems enables the constant evaluation of devices efficiency, making it possible for proactive maintenance and decreasing downtime.

Furthermore, the combination of look these up information analytics supplies beneficial understandings right into functional operations, facilitating better decision-making and resource allotment. For example, predictive analytics can recognize possible failings prior to they happen, additional enhancing maintenance schedules.

Additionally, taking on innovative melting and spreading innovations improves power performance and material yield, which are basic for sustainability in the sector. By accepting these technological advancements, light weight aluminum factories can not only enhance efficiency however also keep a competitive edge in a significantly demanding market (Casting Foundry). Eventually, leveraging technology is essential in driving development and enhancing general operational performance within the industry

Frequently Asked Inquiries

What Prevail Indicators of Devices Put On in Aluminum Foundries?

Usual indications of tools wear in aluminum shops include uncommon noises, reduced performance, enhanced resonance, overheating elements, leakages, and visible deterioration. These indicators commonly signal the requirement for upkeep or potential substitute to stay clear of costly downtime.

Exactly How Can I Train Team for Effective Maintenance Practices?

To educate team for effective maintenance techniques, one can implement hands-on workshops, establish detailed manuals, motivate mentorship programs, and perform normal assessments to examine abilities and expertise, guaranteeing all workers recognize upkeep protocols thoroughly.

What Are the Environmental Laws for Light Weight Aluminum Foundries?

Light weight aluminum foundries are subject to various environmental guidelines, consisting of exhausts control, waste management, and resource conservation. Compliance assurances very little ecological influence, advertising sustainability while sticking to neighborhood, nationwide, and global ecological criteria and laws.

Just How Do Foundries Manage Waste and Recycling of Aluminum?

Foundries manage waste and recycling by implementing systems for collecting scrap aluminum, utilizing advanced splitting up modern technologies, and collaborating with reusing centers to assure effective healing processes, thus reducing environmental impact and promoting sustainability within the sector.

What Are the Prices Connected With Applying Advanced Technologies?

Applying innovative innovations in factories incurs significant prices, consisting of preliminary investment, training, and upkeep expenditures. Nevertheless, the long-lasting benefits, such as increased performance and lowered waste, usually validate these expenditures, bring about enhanced success.

Regular upkeep plays a vital function in the reliable procedure of light weight aluminum shops. In light weight aluminum factories, these approaches make it possible for drivers to anticipate equipment failings before they occur, consequently reducing unexpected downtimes and maximizing operational effectiveness. Utilizing innovative technology has actually come to be progressively important for light weight aluminum shops aiming navigate here to improve functional efficiency. Typical indicators of equipment wear in aluminum shops consist of unusual noises, site reduced performance, increased vibration, overheating elements, leaks, and visible rust. Carrying out innovative technologies in factories sustains substantial prices, including initial investment, training, and maintenance costs.